How long does it take to replace brakes? (2022)

This article includes affiliate links.

The brake system can be a complex unit on modern vehicles. Components of the system have to be correct to be able to stop thousands of pounds of metal. Brake rotor or brake pad replacements can be a DIY mechanic's nightmare or an expert mechanic's "easy" job of the day.

Having the correct knowledge of a brake service can save you time and money. In this article, we will talk about basic brake repair and what it takes to replace your brakes.

What is the braking system?

The brake system uses friction to slow a vehicle down. When the brake pedal is pressed, brake fluid from the master cylinder is pressurized and sent to the brake calipers. The brake calipers' pistons then squeeze the brake pads against the sides of the brake rotor (sometimes known as a brake disc) to slow the vehicle down.

The brake system consists of:

Brake Rotors (brake discs)

Brake Caliper(s) and Brake Caliper Bracket

- With this brake caliper bracket are slide pins and hardware.

Master Cylinder

Brake Booster

Front Brake Pads

Rear Brake Pads

Brake Lines

ABS Pump (anti-lock brakes)

Depending on the vehicle, it could have drum brakes which would have brake shoes, wheel cylinders, adjusters, and other linkages.

How many brake rotors does a car have?

Most modern cars have four brake rotors on the car. There will be two on the front and two on the rear. Depending on the vehicle, your rear brakes could be drum brakes; a more complex style of brake system that is still used today.

How many brake pads are on a car?

A car will typically have four or eight brake pads on it. This, of course, depends on if there are drum brakes on the vehicle.

How long do brake pads last?

Between 10,000 to 20,000 miles is the general rule. Of course, the style of driving can vary the distance brake pads will last. A more aggressive driver may brake harder and more frequently than a reserved driver. Driving habits are the biggest factor in brake pad replacement.

When to replace brake pads?

A vehicle’s brake pads should be replaced when they reach a minimum thickness. This is dependent on the car manufacturers' specifications. A general rule is when the brake pad is at a 1/4 inch or less. Having the brake pads too low can cause a brake squeal or a "metal grinding” noise.

How long do brake rotors last?

Brake rotors can last between 50,000 and 70,000 miles. Driving style will determine how long a brake rotor will last.

When a brake rotor has become too thin, it can cause excessive shaking when applying brakes. This shaking sensation is caused by warping of the brake rotor.

Heat causes the brake rotor to warp.

Some brake rotors are able to be machined or “turned” to have a smooth surface, but this can cause premature warping. Thin brake rotors heat up more quickly.

In most cases, it is best to replace the brake rotor.

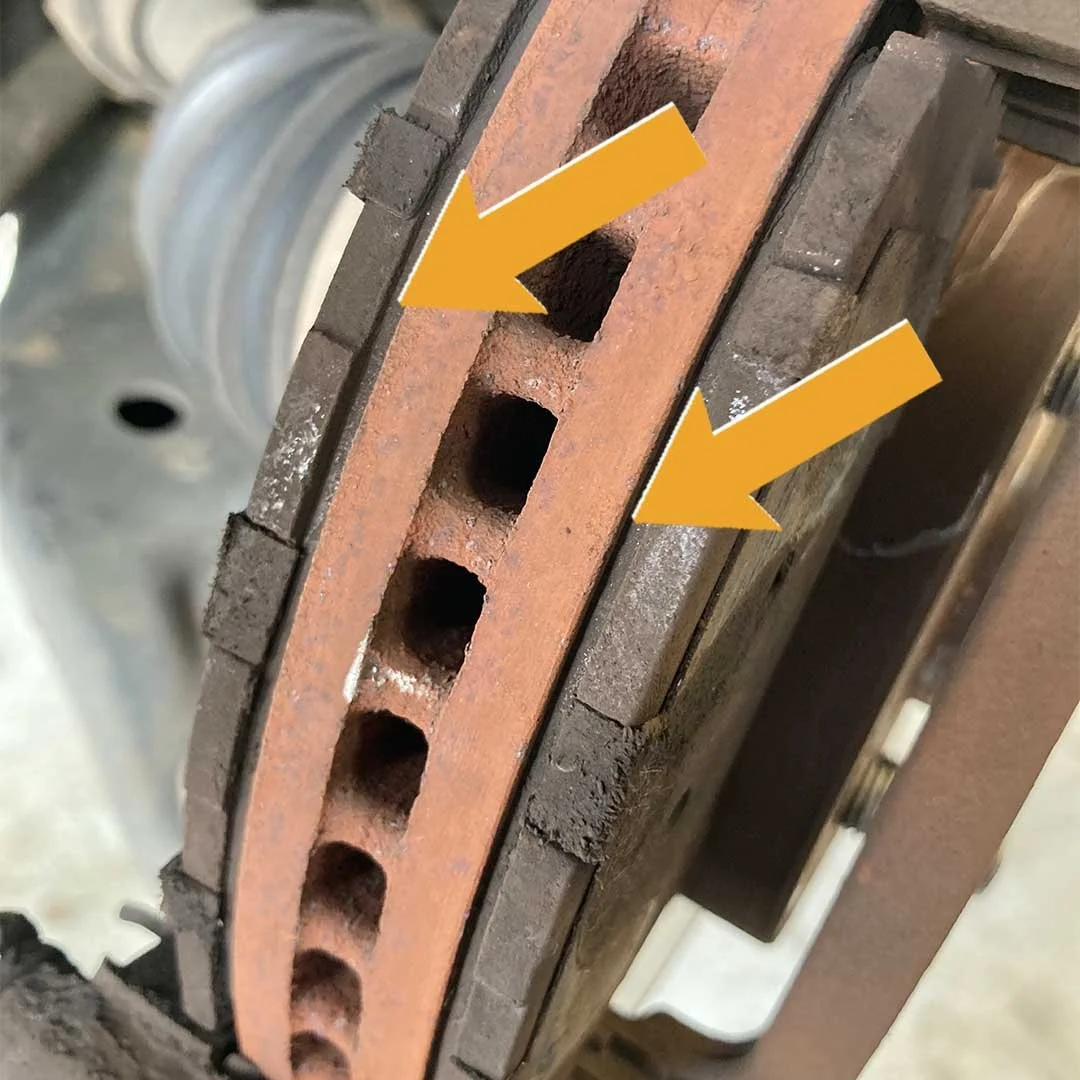

The picture above is a brake rotor that has broken.

The reason this happened is because the owner did not have a routine check-up on their brakes and kept driving even when they heard the a “metal grinding” sound.

How long does it take to change brakes?

A full brake job can take a professional mechanic or brake specialist from 30 minutes to 2 hours. Factors like rust and corrosion can slow a mechanic down when doing a brake job. Some new and luxury vehicles require special tools to compress the caliper piston back. These extra steps can add to the time of a brake job.

Grinding when braking at low speeds?

A grinding noise at low speeds can be a sign of your brake pads getting severely low.

In this picture, there is not enough brake pad left.

How do I know when my brake pads need changing?

If you think you have low brake pads, seek a professional for an inspection.

Squealing or Squeaking sounds

Indicator light or Brake Warning light

On some vehicles, a "low brake pad" warning will appear on the dash or instrument cluster when brake pad wear is too severe. A sensor called a wear indicator located on the brake pad will start to scrub the brake rotor surface when the brake pad is low. When this happens, the wear indicators will need to be replaced too.

Metal “grinding” noise

Vibration when braking

Brake pads less than a 1/4 inch

Brake light indicating low brake fluid

In this picture, there is no brake pad left. The brake pad became so thin that it almost fell out.

What happens if I let my brake pads get too low?

If you know your brake pads are getting low, yet you still drive on them, you may cause damage to your vehicle.

Of course, you won’t have the same braking power as a new set of brake pads.

There is a chance that the rotor will become scarred beyond “turning” or machining. See the picture below for an example.

There is also a chance that the piston inside the brake caliper will push out too far. When this happens, the piston may not go back in or may become damaged and not work properly. See the picture below for an example.

What do I need for a brake job?

New rotors

New brake pads

Brake lubricant

Car jack and jack stands

Socket set

For caliper, caliper bracket, etc.

Lug nut wrench or Impact with impact sockets

Be sure not to strip the lug nuts when removing them.

Torque wrench

To torque bolts to proper specification.

Brake piston tool and brake caliper hanger

Flat surface and wheel chocks

Your car may need specialty tools. Following a quick Youtube video or blog on your specific vehicle can factor in the need for specialty tools.

Don't have these tools? There is good news! Ask your local auto parts store if they have a tool rental program. They may be able to provide you with the exact tool you need.

Safety Tip: After replacing your brakes, pump the brake pedal several times to feel a strong, hard pedal before driving.

Important Tip: New brake pads need to be “burnished” into the new rotors to ensure the best braking performance.

It’s important to not allow your brake calipers to hang by the brake line. The weight of the brake caliper can stretch and damage the brake line.

A brake caliper hanger is used to hold the brake caliper so it does not stretch the brake line.

A bungee cord can also be used instead of a brake caliper hanger.

How to find torque specs for your car?

After installing new brakes, the vehicle should have the bolts torqued to specification.

Every bolt that has been loosened has to be tightened to the correct tightness before driving.

Alldata DIY can provide you with the correct torque specifications for your vehicle.

How do I find the right brake parts for my car?

Simply go to your local auto parts store and they can help you order front brakes and rear brakes for your car. Be sure to order the correct type of brake pad for your vehicle. Look into higher-quality brake pad materials. Higher-quality brake pads may reduce brake wear and extend the life of your brake pads.

Don't forget to ask about a tool rental program.

Be sure to check each component you buy from the auto parts store. Some vehicles come with different styles and sizes of brake pads and rotors for the front and rear.

Always compare the brake pad and rotor for the proper hardware and size.

Some brake pads go on the vehicle a certain way. Be sure to keep the old brake pads oriented in the same directions they came off to ensure the new brake pads go on the same way.

How can you take care of your brakes?

Proper brake inspection can enhance the life of your brakes.

Brake fluid condition - make sure it is clean and not low

Brake pad thickness - make sure there is not a lot of wear.

How does the pedal and steering feel when braking?

Visual inspection of brake components for excessive wear or leaking brake fluid.

Evaluate your personal driving style.

It may be time to avoid higher speeds and hard stops.

Safe driving goes hand in hand with proper braking. There are plenty of vehicle owners that rely on their auto shop to provide them with a complete report of their brake system to make sure it is in good condition. If you have any concerns about your brake system, seek a professional mechanic immediately.

The best way to keep brake problems from slowing you down is to apply regular visual and physical inspections to your maintenance services or oil change. Safety issue(s) can be a life or death situation. Proper maintenance of a vehicle can save money in the long run.

Disclaimer and Disclosure:

Due to factors beyond the control of DiagnosticMechanic.com, it cannot guarantee against unauthorized modifications of this information, or improper use of this information. DiagnosticMechanic.com assumes no liability for property damage or injury incurred as a result of any of the information contained in this website. DiagnosticMechanic.com recommends safe practices when working with power tools, automotive lifts, lifting tools, jack stands, electrical equipment, blunt instruments, chemicals, lubricants, or any other tools or equipment seen or implied in this website. Due to factors beyond the control of DiagnosticMechanic.com, no information contained in this website shall create any express or implied warranty or guarantee of any particular result. Any injury, damage or loss that may result from improper use of these tools, equipment, or the information contained in this website is the sole responsibility of the user and not DiagnosticMechanic.com.

DiagnosticMechanic.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. In many of our case studies, articles, and tool reviews, we may earn a small commission when readers purchase products through our links.